Food quality control involves a systematic approach to maintaining desired standards throughout the entire food supply chain – from the farm and ingredient sourcing, through processing and packaging, all the way to the consumer’s plate. Ensuring the quality and safety of food is critical, influencing public health, consumer trust, and business success.

What is Food Quality Control?

Food quality control (FQC) refers to the set of procedures, activities, and systems used to ensure that food products consistently meet predefined quality standards and safety specifications. It involves meticulous monitoring, inspection, testing, and documentation at various points to guarantee product safety, regulatory compliance, consistency, and overall consumer satisfaction. This encompasses everything from raw agricultural ingredients to complex processed foods.

Defining Quality in Food

Food quality encompasses a wide range of attributes beyond basic safety:

- Safety: Free from harmful biological (bacteria, viruses), chemical (pesticides, cleaning agents, allergens), and physical hazards (metal, glass).

- Nutritional Value: Meeting declared nutritional content and label claims.

- Sensory Characteristics: Acceptable taste, texture, aroma, and appearance.

- Physical Characteristics: Correct size, shape, weight, volume, consistency, and free from defects.

- Compositional Integrity: Accurate formulation and ingredient usage in processed foods.

- Shelf Life: Maintaining safety and quality attributes for the expected duration.

- Packaging Integrity: Ensuring packaging protects the product and is properly sealed and labeled.

- Regulatory Compliance: Adhering to local, national, and international food laws and standards.

Key Stages for Food Quality Control

Effective FQC must be integrated throughout the entire food journey:

- Ingredient Sourcing & Agriculture: Verifying supplier quality, implementing Good Agricultural Practices (GAP), ensuring raw material specifications are met.

- Receiving & Storage: Inspecting incoming materials, proper storage conditions (temperature, humidity) to prevent degradation.

- Processing & Manufacturing: Implementing Good Manufacturing Practices (GMP), Hazard Analysis and Critical Control Points (HACCP), monitoring critical process parameters (time, temperature, pH), ensuring hygiene and sanitation.

- Packaging: Checking packaging material quality, seal integrity, correct labeling (including allergen information and date codes), and fill accuracy.

- Finished Product Testing & Release: Final product sampling and testing against specifications before distribution.

- Distribution & Retail: Maintaining appropriate conditions during transport and storage, managing stock rotation (FIFO – First-In, First-Out).

Why is Food Quality Control Crucial?

Implementing robust FQC systems is non-negotiable for several reasons:

Protecting Consumer Health

This is paramount. FQC prevents foodborne illnesses and ensures food is safe for consumption by controlling hazards at every stage.

Meeting Regulatory Requirements

Compliance with food safety regulations (e.g., FDA, USDA standards) is legally mandated and essential for market access.

Building Consumer Trust and Brand Reputation

Consistent quality and safety build consumer confidence, loyalty, and protect the brand’s image from damaging recalls or incidents.

Reducing Waste and Improving Efficiency

Identifying issues early minimizes costly recalls, product reprocessing, and waste, optimizing operational efficiency.

Ensuring Product Consistency

Consumers expect products to be the same every time they purchase them. FQC ensures uniformity in taste, texture, and appearance.

Key Methods for Food Quality Control

A variety of methods are essential for comprehensive FQC:

Inspection and Sampling

Systematic visual checks and statistical sampling of raw materials, in-process items, packaging, and finished goods to identify deviations and defects.

Laboratory Testing

Utilizing chemical, microbiological, and physical tests to detect contaminants, verify nutritional content, confirm shelf life, check for allergens, and assess sensory attributes.

Standardization and Specification Management

Establishing clear quality standards and specifications for ingredients, processes, and finished products, and ensuring adherence. This includes grading for raw commodities and consistency checks for processed items.

Implementing HACCP Plans

A systematic, preventive approach (Hazard Analysis and Critical Control Points) specifically designed to identify, evaluate, and control food safety hazards throughout production.

Adhering to Good Manufacturing Practices (GMP)

Following established guidelines for operational procedures, personnel hygiene, facility sanitation, equipment maintenance, and process control within manufacturing environments.

Process Control Monitoring

Continuously monitoring critical control points during processing (e.g., cooking temperatures, mixing times, pH levels) using sensors and instrumentation to ensure parameters stay within safe limits.

Supplier Quality Assurance

Auditing and verifying that suppliers meet required quality and safety standards for ingredients and materials.

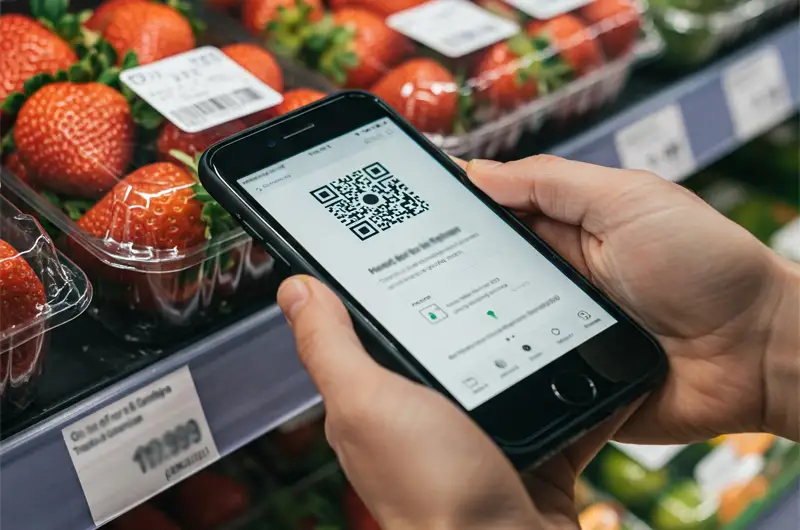

Traceability Systems

Implementing systems (e.g., batch codes, barcodes, RFID, blockchain) to track ingredients and products throughout the supply chain, facilitating efficient recalls if necessary.

Packaging Quality Control

Inspecting packaging materials, checking seal integrity, verifying label accuracy (especially allergens, dates), and ensuring packaging functionality.

Challenges in Maintaining Food Quality

Achieving consistent food quality faces ongoing challenges:

Supply Chain Complexity

Global and intricate supply chains increase the number of potential points where quality can be compromised.

Variability of Raw Materials

Natural variations in agricultural products due to weather, pests, and growing conditions can impact processing consistency.

Maintaining Hygiene and Preventing Cross-Contamination

Especially crucial in processing environments, managing allergens and preventing microbial contamination requires constant vigilance.

Cost of Implementation

Establishing robust FQC systems, including testing labs, trained personnel, and technology, requires significant investment.

Evolving Regulations

Keeping up with changing food safety laws and standards across different markets can be complex.

The Future of Food Quality Control

Technology and changing consumer expectations continue to shape FQC:

Advanced Technology Integration

IoT sensors for real-time monitoring (temperature, humidity), AI for predictive analytics and visual inspection, blockchain for enhanced traceability, and rapid pathogen detection methods are becoming more prevalent.

Increased Demand for Transparency

Consumers want more information about where their food comes from, how it was produced, and its ingredients, driving demand for better labeling and traceability.

Focus on Sustainability and Ethical Sourcing

Quality control is expanding to include verification of sustainable practices and ethical sourcing claims.

Food quality control is a vital, multi-faceted discipline essential for the modern food industry. It requires a holistic approach, integrating best practices like GMP and HACCP with advanced technologies and a commitment from everyone involved in the food supply chain – from farm to fork – to deliver safe, reliable, and high-quality food products.

Latest Posts: